Safety is the number one priority at Armistead Mechanical, Inc. for our employees, clients and subcontractors. Armistead continually emphasizes the importance of safety and is committed to operate in full compliance with all safety codes and regulations. We have a Safety Manager on staff to enforce safety policies and procedures with all personnel. From the field mechanic….to top management….all personnel participate in our in-house training programs…and those of our trade organizations.

CORPORATE SAFETY POLICY

It is the policy of Armistead Mechanical, Inc. to provide a safe and healthful work environment for each of its workers. Each employee in this company, from the President to the newest worker, shall work diligently to achieve zero occupational injuries and illnesses. Armistead Mechanical will pursue our goal of zero work-related injuries through a process of continuous improvements. We will foster and maintain a work environment that encourages free and open expression of safety concerns where employees have no fear of reprisal for reporting concerns. We support a “Don’t Walk By” program giving all employees the authority to stop any unsafe procedures and encourage them to take responsibility for keeping each other safe.

All of our workers are provided with the necessary personal protective equipment to keep them safe on the job and are required to use it at all times.

We have a zero tolerance policy for drug or alcohol use, violence, and harassment of any kind in the workplace whether it is in the office or in the field.

SAFETY TRAINING

Armistead is committed to safety training and education for every member of our team. Every journeyman goes through five years of the UA apprenticeship training program before moving through other levels of certification based on experience, continued training and skill. Field and management participate in rigorous MCAA conferences and seminars, and OSHA training. Our on-staff Safety Manager conducts regular jobsite inspections and is a resource to our field foremen on safety issues, such as job safety analysis or crane and helicopter critical lift plans. Armistead adapts to client safety requirements by bridging your safety requirements to our own. This includes drug testing, background checks and TWIC cards.

Management, project managers and field personnel are required to have 10-hour OSHA certification before working on any Armistead Mechanical project. In addition, Foremen must complete OSHA 30-hour training. Our on-staff OSHA-certified Safety Trainer instructs employees on topics specific to the project-at-hand, whether it be confined space, fall protection, hazard communication or lockout/tagout.

All workers on Armistead jobsites participate in regular safety meetings, including subcontractor employees.

Armistead provides trained personnel for soldering and welding processes in the mechanical industry, including NFPA 99 medical gas. All employees that perform these services are tested and certified according to project requirements.

HVACR Service Technicians receive continuing education through the MCAA, MSCA as well as via manufacturer programs and seminars. It is critical to stay current with new equipment, technology, and safety requirements.

SAFETY RECOGNITION

Northeastern Subcontractors Association Gold Award

2009 through 2018

ConocoPhillips (Phillips66) Safety Excellence Award

2008 through 2010

Anheuser-Busch Proud to Be Safe Award

2005

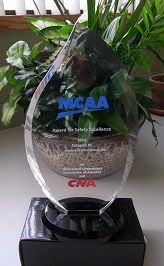

MCAA and CNA Award for Safety Excellence

2014 and 2018

MCAA Safety Statistics Program Commendation

2005 through 2014

NJ Governor’s Occupational Safety & Health Award

2006 through 2017